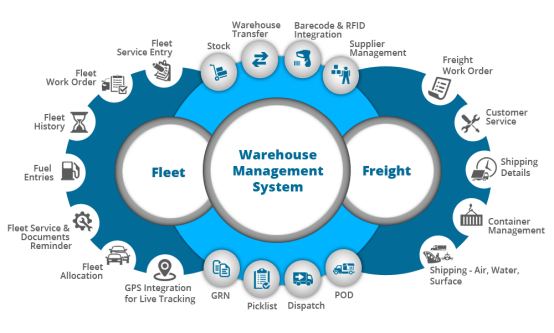

Traditional Warehouse Management

It is actually the part of ERP or inventory management system for traditional warehouse management software ,The core is finance inventory management and more focus on finance recording and do not care about actually warehousing,it will cause material difficult to check ,low updating for inventory ,hard operation and high management cost especially low accurate rate .Most of enterprises 's inventory accurate rate can not reach to 70%

Barcode WMS (warehouse management system )

With barcode technology and modern warehouse management raising ,barcode technology has been brought in warehousing for avoiding shortage with traditional warehousing .you can use barcode to mark material , storage , pallet even warehouse out instruction sheet . Using the special equipment (such as barcode printer , PDA ,AP, PC, etc ) and related software system to scan ,check and control inventory at logistic nodes .

1. Improving the efficiency and accurate rate ;

2. Controlling items to be off shelves follow right strategy(such as FIFO)

3. Guiding the item to put right position

4. Convenience and quick for inventory

Features of barcode WMS

◇ Storage management

Inventory is managed according to storage dividing and easy to store material as classification ,on shelf or off shelf and checking material's storage location even material's quantity and catalogue .

◇ Higf inventory accurate rate :

The inventory data update mainly input the ERP by manual now .and problem is input system slowly and easy to make mistakes cause inventory data error .With our system can make sure customers data update in time and reduce manual mistakes .Maintaining enterprise's normal suppling and customer requests .

◇ In-out priority and reduce wasting

Arrange the early storage goods to ship out and reduce the wasting when items down shelf and warehouse-out .

◇ Avoiding storage error and miss

Use storage instruction sheet ( purchase order ,sales order and produce order ) to verify the correct for item name and quantity ,also make warning or refusing during mistakes happened .

Problems with Barcode WMS system

1:Low scanning rate when lots of items and have to match barcode label when we scan .It has increased extra working for workers .If barcode labels are indistinct or damaged can not make inventory even we cost too much time to replace .

2:Limit the forklift 's working .

3:Barcode stickers can not reuse . print and can not change the version ,only working one time ,

4:Does not have function on anti-theft with barcode technology .We can not control when goods warehouse out and replace the enterprise loss

RFID Warehouse Management System

RFID ( Radio Frequency Identification ) , it is contact-less automatically identification technology .It can get data through RFID signal automatic identify the target object without manual intervention .As the upgrade technology RFID is water proof ,antimagnetic ,high temperature resistance, long working life ,longer reading distance , data encrypted and bigger store memory than previously barcode technology . RFID technology will make the revolutionary change for our nowadays warehousing

1. Warehouse in and out automatic : UHF handheld reader reading distance can reach to 2-5 meters and UHF table reader can reach to 3-12 meters (will depend on RFID antenna size and reader power ) . If we use active RFID sticker and reading distance can reach to 30 meters .it will work out manual scanning problem than barcode system and improve the forklift work efficiency even controlling the labor cost

2. Numbers of RFID tags are read within seconds : reader can read the date when RFID tags enter the reading area and read numbers of tags with RFID anti-collision technology and table reader .It will greatly improve the scanning rate and reduce the labor cost .

3. Unhindered reading ; barcode label can not hide the barcode image when we scan but RFID label or tags can be read direct and good penetrability .

4. Large memory : barcode's store capacity is 50 Bytes and QR barcode also can store memory 2-3000 characters ,but RFID 's maximum store memory can reach to mega Bytes even it is developing for more larger memory .

5. Long working time : RFID 's wireless communication feature will make them can work under dust and oil contamination environment . Rolling RFID will make data store into chip and can avoid any destroy or stained , normally can work 10 years and 100 000 times read and re-writing .

6. Reuse : We can change the RFID tags' encoding and benefit is we can reuse them many times than traditional barcode only use one time . it will greatly reduce the consumable cost

7. Security : RFID tags can not embed into different shape or material but also can set up password for protecting data .and make them more safe .

8. Different shape and smaller size : RFID tags can be smaller size and different shape for matching paper size and printing quality , It will be easy to embed in different shape and material .

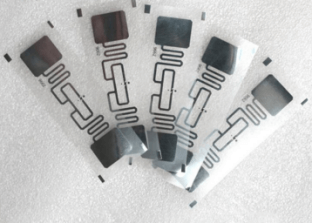

RFID Tag

RFID Tag is made of tag , ,antenna , reader

Tag : it is made of coupling element and chips . each tag has unique electronic code , high memory tag has user area .

Reader:read or re-write the RFID tags can be table reader and handheld reader

Antenna:transmit the RFID signal between tags and readers .

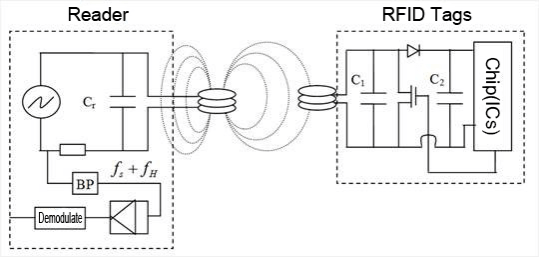

RFID technology working principle

RFID is not complicated for its working , Reader transmits the RFID signal through antenna when RFID tags enters the reading area and transmit data information after tags get power and active the RFID chips . Reader receives the signal from RFID tags and feedback to computer . Finally sending command signal to control reader to finish read and re-write after computer identifies the RFID tags.

Compare with traditional barcode

| Barcode Tag | RFID Tag |

| Reading distance within 5cm | Long reading distance and UHF RFID tags can be above 6 meters . |

| Only can read one piece each time | Can read hundreds of tags at same time |

| Can not penetrate material | Can penetrate material such as wood |

| Small store memory | Large store memory |

| Easy to destroy | Long working time and work in different environment |

| Cannot reuse | Can reuse |

| Normally in paper material | Small size and different material to embed such plastic , ceramic . |

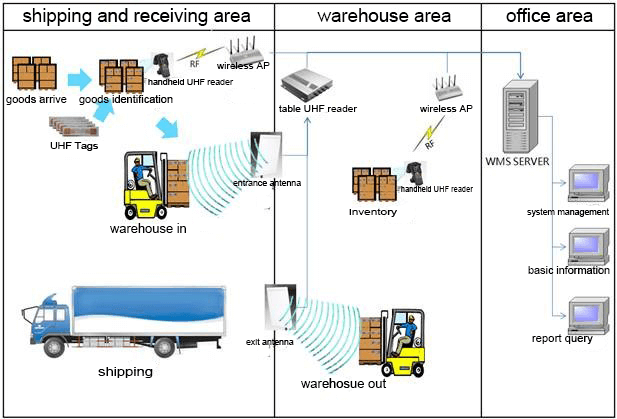

Solution Concept ;

Working with RFID technology ,we can stick into RFID label on each goods or stick on pallet ,then setting up the RFID antenna and reader at the entrance and exist of warehouse . RFID tags can be read and check warehousing quantity after pallet go through the gate . Finally we use warehousing software to operate the warehousing .

Put the RFID sticker on shelf and set up reader and vehicle -mounted on forklift at same time .it can make connecting between goods and shelf .It can not only recode the right position for goods , but also can offer position information for forklift and easy to deploy

All inventory procedures will operate with handheld reader . Staff take the handheld reader to read data and check all goods then understanding the related information of goods .even can input the goods name and find accurate position in warehouse.

Structure of Solution

Feature of Solution

Identification batch goods at same time .

Save time for labels printing and matching when we use RFID handheld UHF reader to connect RFID labels and goods

1: When goods arrive and make RFID sticker stick on the goods ( do not need to match them )

2: Chose the goods name , specification in handheld UHF reader when all goods finishing RFID stickers

3: Use handheld UHF reader to read finished RFID sticker goods and system can make connecting between RFID sticker and goods automatic and finish the identification ,

RFID Goods Allocation

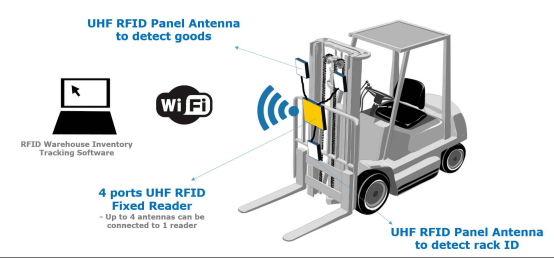

Use RFID sticker to identify goods allocation and can make sure we put goods in right position after forklift's wireless PC and reader to read RFID stickers .Normally it is use anti-metal RFID UHF tags

Quick scanning

Can scan or read hundred of RFID tags at same time and greatly improve the efficiency of warehousing and reduce the management cost .

Advantage in storing

Large memory and do not effect the memory structure even small size RFID tags .

Reuse

Normally can work over 10 years and R&W above 100 000 times .

Improve the using for forklift

set up reader and vehicle -mounted on forklift at same time .it can make connecting between goods and shelf .It can not only recode the right position for goods , but also can offer position information for forklift and easy to deploy

Warehouse in automatic

When there is new command for putting in storage :

1: System can assign the free time forklift according to forklift operation plan and send command to tablet PC of forklift

2:The reader of forklift to read pallet and compare the information with storage in order to make sure right recommend after forklift 's tablet PC to get command and lift the pallet .

3:The entrance gate will open and send background with forklift and pallet reading information after forklift go through the warehouse entrance and reader to read the RFID sticker in forklift .

4:Reader scans the goods allocation sticker and confirms to match the target goods allocation with command then goods on the shelf and send back command to host system after forklift arrives the target goods allocation ,

5: host system confirms goods in warehouse and generate list for updating database even recording this operation .

Warehouse out automatic

When there is new command for warehouse out

1: Host system selects free time forklift and sends the command to tablet PC of forklift

2:According to the pallet information from tablet PC and arrive the target goods allocation .reader read the goods and pallet's RFID labels then matching with out warehouse command and confirm the goods off the pallet . If only take off partial goods and have to need manual to select on the target pallet .

3:Finishing the goods selection and send command to host system .

4: Selecting all goods and using UHF RFID handheld reader to scan all pallet RFID stickers then matching the bill of delivery order , if without any mistakes and take back the pallet RFID sticker then sending command to host system .

5: Host system confirms the delivery and generates the sheet for updating database , final record this time operation .

6: All details in list and into warehouse , collect data match with list data then sending the result to customs supervision system .

High efficiency inventory

With RFID group reading feature we can check inventory quickly and great improve warehouse management and save much time for checking .

Anti-theft

System checks goods and warns automatic if goods do not need to delivery when goods out of warehouse .

The implementation of benefit

Stock available can up from 5% to 10%

The speed of delivering can raise 10%

Labor cost can reduce 20%

Warehouse managing charge reduce 30%

Expanding the capacity of warehouse and reach to 20%

Reducing the destroy rate and expired goods' write off can reach to 20%

Working with RFID warehouse management system can make sure each procedure 's speed and correct in warehouse management . Also make sure enterprise can get accurately real data and control stocks .Comparing traditional warehousing we can not only check the location of every goods but also improve the management working efficiency.

Copyright © Shenzhen Zhixin RFID Tag Co., LTD All Rights Reserved | Sitemap Technical Support: